GIR: Get it Right

Title: Co-Lead Industrial Designer

Duration: June 2018 - June 2021

Headquartered in Irvine, California GIR: Get it Right is an award-winning kitchen appliance/utensil brand. Disrupting the industry with planet-friendly solutions breaks the norm for largely populated corporations. GIR’s mission is to provide uncompromising focus on quality, attitude, and constantly asking the question “why?”

My job duties as the Industrial Design Co-Lead were to design, manage, and cross communicates across our multidisciplinary team. At GIR I was responsible for ensuring new products represent the core competencies of the brand. Cross communicating our design intent from concept to manufacturing is a key role in my daily tasks.

My Thought Process

This is a brief highlight of products I’ve created and oversaw during my tenure at GIR: Get it Right. Each product had its very own needs and wants but every single one shared my common principles of creating strict innovative feature sets which pushed the brand forward.

-

This is the very beginning of the product development process, where I start with concepts from mild to wild with a targeted beneficial feature sets in mind.

-

This is where concept starts to turn into reality, by keeping common manufacturing methods in mind with a nod to creative hardware design to optimize a balance in BOM cost and quality of end product.

-

This is where I ensure proper industrial design elements for individual products are carried through manufacturing verification tests.

DVT | EVT | PVT | MP

-

Once individual products receive my approval, this is where we begin to incorporate creative exporting methods to ship products from overseas to the associated distribution centers.

Potato Masher

Materials Used: Platinum Grade Silicone | Nylon Insert | 304 Stainless Steel | Polypropylene

Manufacturing Method Used: Silicone Compression Molding | Metal Stamping | Plastic Injection Molding with Co-Molding of Stainless Steel

Ideation to Mass Production In-Hand at DC: 5 Months

Ideation Phase

DFM Stage & BOM Cost Control

Mass Production

Spaghetti Spoon

Materials Used: Platinum Grade Silicone | Nylon Insert

Manufacturing Method Used: Silicone Compression Molding

Ideation to Mass Production In-Hand at DC: 8 Months

Ideation Phase

DFM Stage & BOM Cost Control

Mass Production

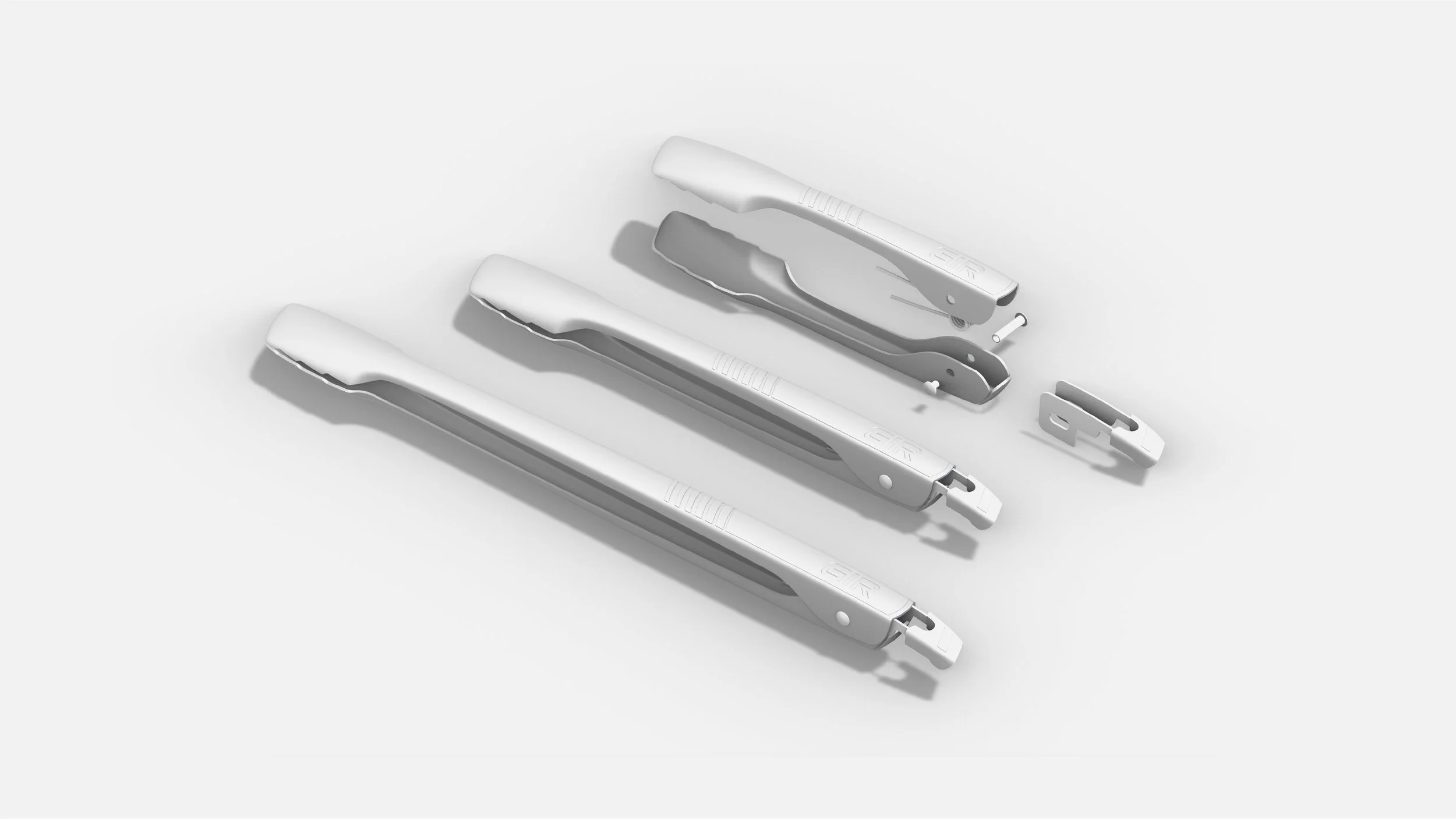

Slide Locking Nylon Tongs

Materials Used: High-Temperature Resistant Nylon | Thermoplastic Rubber | 304 Stainless Steel

Manufacturing Method Used: Rubber Injection Molding | Plastic Injection Molding | Metal Stamping

Ideation to Mass Production In-Hand at DC: 10 Months

Ideation Phase

DFM Stage & BOM Cost Control

Mass Production

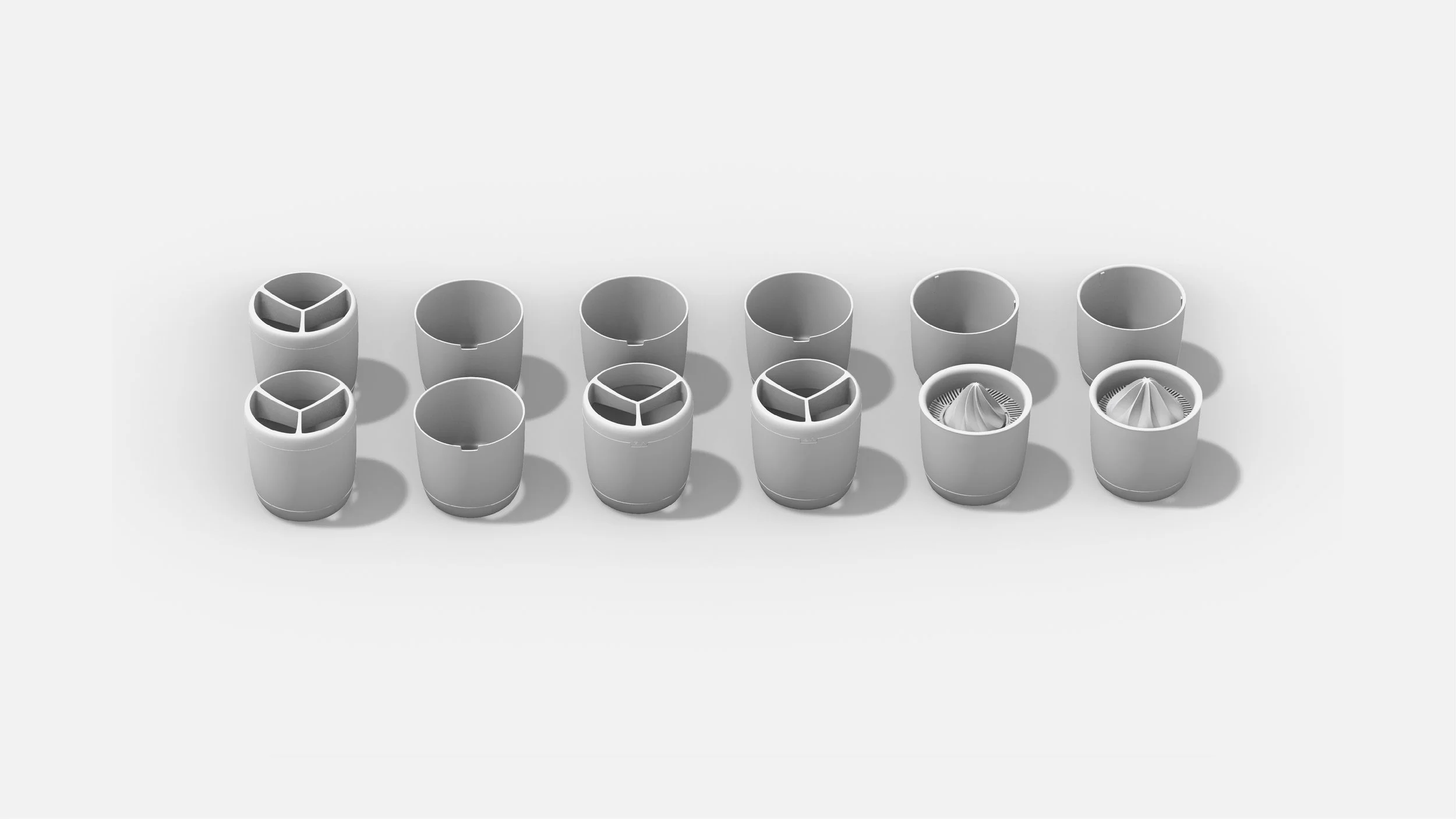

Ultimate Tool Container

Materials Used: Platinum Grade Silicone | Polypropylene

Manufacturing Method Used: Silicone Compression Molding | Plastic Injection Molding

Ideation to Mass Production In-Hand at DC: 10 Months

Ideation Phase

DFM Stage & BOM Cost Control

Mass Production

Silicone Face Masks

Materials Used: Platinum Grade Silicone

Manufacturing Method Used: Silicone Compression Molding

Ideation to Mass Production In-Hand at DC: 5 Weeks

Ideation Phase

DFM Stage & BOM Cost Control

Mass Production

30 New Product Innovations Made Under My Leadership | Over 300 New SKUs Created

Materials Used For All Product Creation: Platinum Grade Silicone | Nylon Insert | 304 Stainless Steel | TPR | Stainless Steel Wire | Polypropylene

Manufacturing Methods Used: Silicone Compression Molding | Injection Molding | Metal Bending | Silicone/Rubber Injection Molding