Five Two by Food52

Title: Co-Lead Industrial Designer at GIR: Get it Right

Products Created by GIR: Get it Right

During my tenure at GIR: Get it Right, our goal is to create products that changed the perspective of the kitchenware industry. Using small innovations to achieve an end goal which yields a much stronger product that bears the aggressive housewares market. Our client during the time, Food52 came to us for this exact reason.

Below you will see the products I created for the Five Two by Food52 brand. This speaks great lengths of how I ensure a perfectionist mentality is carried over from initial ideation to mass production.

My Thought Process

This is a brief highlight of products I’ve created and oversaw for the Five Two brand. Each product had its very own needs and wants but every single one shared my common principles of creating strict innovative feature sets which pushed the brand forward.

-

This is the very beginning of the product development process, where I start with concepts from mild to wild with a targeted beneficial feature sets in mind.

-

This is where concept starts to turn into reality, by keeping common manufacturing methods in mind with a nod to creative hardware design to optimize a balance in BOM cost and quality of end product.

-

This is where I ensure proper industrial design elements for individual products are carried through manufacturing verification tests.

DVT | EVT | PVT | MP

-

Once individual products receive my approval, this is where we begin to incorporate creative exporting methods to ship products from overseas to the associated distribution centers.

Rollable Drying Rack

Materials Used: Platinum Grade Silicone | Stamped Metal Insert

Manufacturing Method Used: Silicone Compression Molding | Metal Stamping

Ideation to Mass Production In-Hand at DC: 8 Months

3D CAD Exploration

Final Design Refinement

Mass Production Model

Compost Bin

Materials Used: Polypropylene

Manufacturing Method Used: Plastic Injection Molding

Ideation to Mass Production In-Hand at DC: 12 Months

3D CAD Exploration

Final Design Refinement

Mass Production Model

Rolling Pin

Materials Used: Teak | Platinum Grade Silicone

Manufacturing Method Used: Mass Production Wood Lathe | Laser Positioning Etching | Silicone Compression Molding

Ideation to Mass Production In-Hand at DC: 6 Months

3D CAD Exploration & Design Refinement

Mass Production Model

Pastry Set

Materials Used: Platinum Grade Silicone | Steel with Brass Plating | 304 Stainless Steel

Manufacturing Method Used: Silicone Compression Molding | Metal Diecast with Plating | Metal Stamping

Ideation to Mass Production In-Hand at DC: 11 Months

3D CAD Exploration

Final Design Refinement

Mass Production Model

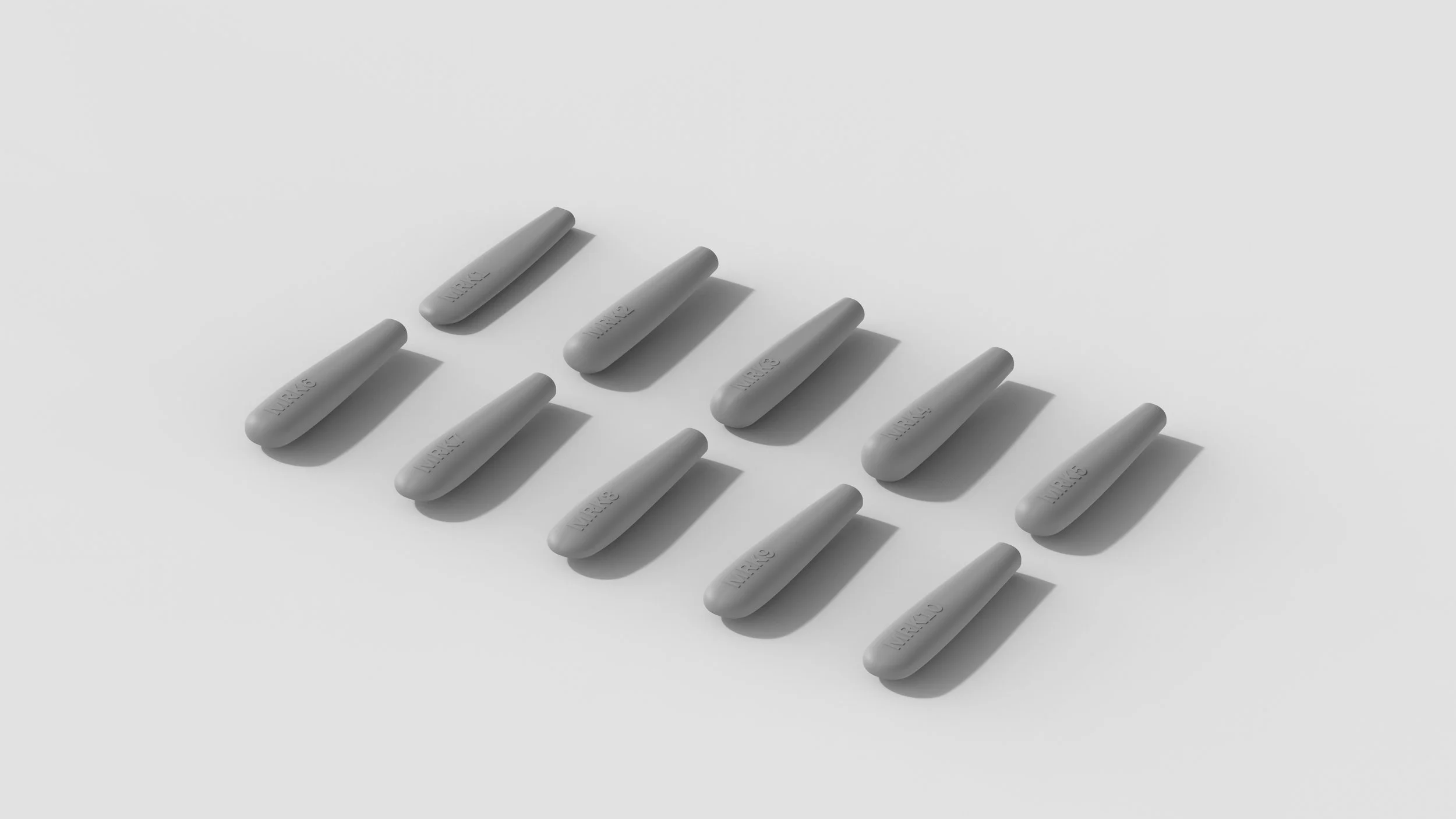

Airtight Silicone Lids

Materials Used: Platinum Grade Silicone

Manufacturing Method Used: Silicone Compression Molding

Ideation to Mass Production In-Hand at DC: 3 Months